Coloring the hair has been a practice that is going on since ancient times. The ingredients, however, have changed with time. It is the need of the hour to have our hair colored or else the grey hair would look devastating! Moreover, people these days are more adaptive of the fashion trends and change hair color as the season changes its colors.

Do you love to have your hair colored? Yes? Do you know how hair color is made? No? then scroll down to know it as we have a brief history of this practice along with the raw material, manufacturing process and the quality control of making the hair color. We are sure you will find this fascinating along with some information on how often you should color your hair.

How Hair Color Is Made- Raw Materials, Manufacturing Process, And Quality Control

Hair coloring was a technique used to add in pigments of various colors in the hair follicles. This was even done back during the time when ancient Egyptians and Greeks walked on this earth. They made the dyes from plants and metals compounds or even mixed both to get some color. Even today, the European hair color makers use plant extracts in their product to achieve some colors. Gaston Boudou, A French hairdresser marketed a standardized range of hair dyes back in 1910. The hair dyes that we used today were initially made in 1950s that eliminated the preparation of hair dying into a one-step procedure.

Moreover, here are Different Silver Hair Color Ideas and Tips for Maintenance and Hair Color Care.

Raw Materials

The commercial hair colors have a complex mixture with a dozen of ingredients mixed in it. They use modifiers, antioxidants, alkalizes, soaps, ammonia, wetting agents, fragrance, and a variety of other chemicals in their product.

The hair dyes need a developer that goes along with it to regulate the color. This developer mainly contains the hydrogen peroxide and some other chemicals, which articulate the color in the hair follicles. With this, here are Best Hair Colors for Dark Skin!

Manufacturing Process

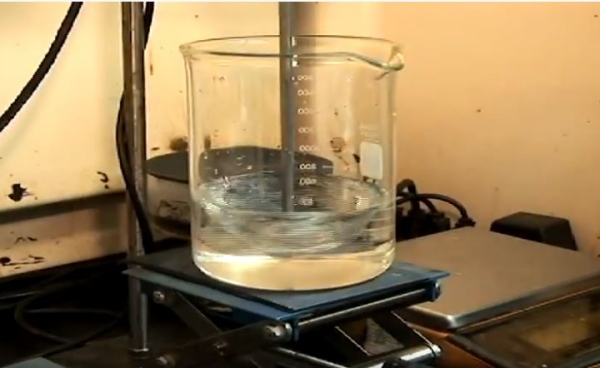

The first step is the fill in the water. However, it is not regular tap water. It is de-ionized water, which means that the water is filtered to remove all the contaminants from it.

This water needs to be such that it does not dominate the other ingredients that will be going into it. Hence, it is just there to help the mixture form and not to react with it.

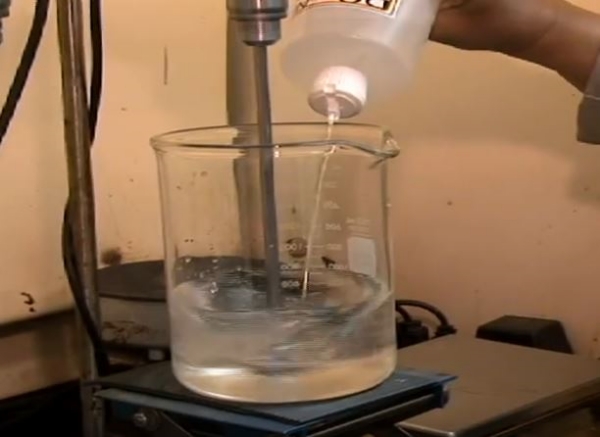

Next, the antioxidants are added to the water that doesn’t let the product stale in the tube. Sodium sulfide and sodium insole are used in this process.

Next, a solvent and a humectant are added to the mixture so that the dyes don’t dry it in the tube. Most of the time it is propylene glycol that acts as both.

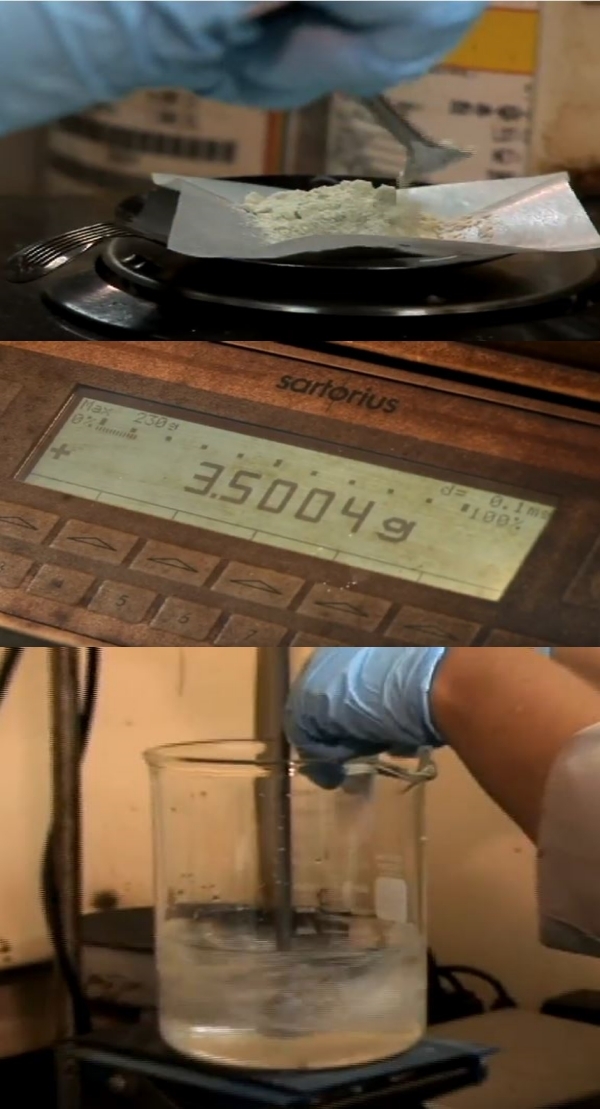

Next, the dyes are weighed. The measurement is very essential as it regulates the formation of the color. The scale is accurate to 11000 of a gram.

The dyes do not mix in the cold water. Therefore, the temperature is raised to 75 degree Celsius.

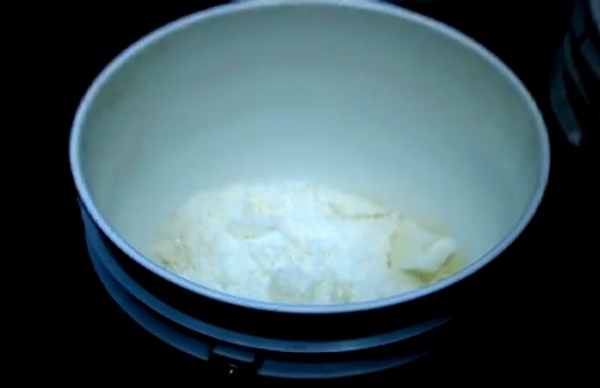

This dry mixture contains different hydrolyzed proteins and other ingredients that will be melted and added to the water to create a creamy base.

When the two are added, an emulsion is created and it becomes the conditioning base of the product. To enhance the quality of the product, additional conditioners are again added to the mixture.

The product should now be cooled down to 40 degree Celsius so that alkalizes can be added to them.

Since the color is a higher lifting blonde shade, a mixture of ammonium hydroxide that will create a shade that is required. The mixture is only mixed enough that when it comes in contact with the hydrogen peroxide in the developer, the mixture will have an ammonium content of 1.4%. The last ingredient to go in the mixture is the fragrance.

Also read: Best Winter Hair Color Ideas (Be the New Girl in Town)

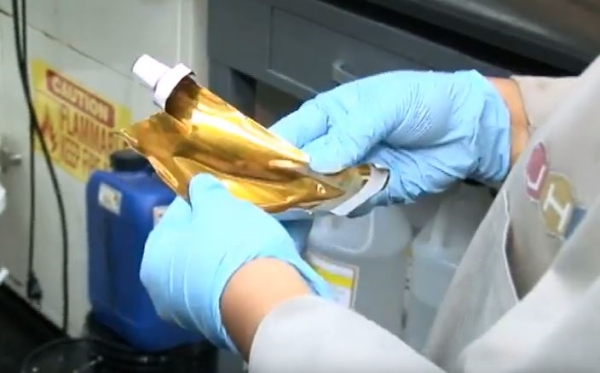

Packaging

The hair color that is made is filled in the tubes. These tubes are not simple plain tubes. They are specially coated internally to prevent oxidation. This way no air gets inside the tube hence no adulteration of the product happens.

Quality Control

The toxicity of the product is kept under the range given in the regulations by the government. All the product is tested well in the laboratories before the ratios and compounds reach the factory to be produced. Moreover, the workers to check the batch before it goes in the containers.

Aloes read: Different Hair Color Ideas for Short Hair That is how hair color is made. We hope you liked reading about it. This was the making process of blond hair color. You can have some best hair color for fair skin from here. Take care of your hair as excessive chemical treatments may destroy the hair folli

Reply