Who hasn’t seen the mommy pull a baby wipe out of a packaged stack to clean her little one’s messy bum. And who hasn’t seen makeup laden youtubers using these wipes to get layers of cosmetics off their face. Baby wipes are a necessity these days. In fact, we have seen them being used in place of tissues. But have you ever wondered How Baby Wipes are Made | History, Materials & Manufacturing Process or where they come from? Well, if yes, then we have loads of interesting info for you here.

How Baby Wipes are Made | History, Materials & Manufacturing Process

ALSO READ – How Nail Polish is Made | Materials, Manufacturing and Quality

Let’s First Understand What Baby Wipes Are

Baby wipes are cloths that are use-and-throw in nature. They are primarily meant for babies. Their sensitive skin needs better care, after all! Baby wipe sheets are made of non-woven fabrics saturated with some cleansing solution made with gentle ingredients. They are stored in a way that facilitates easy dispensing and their moisture doesn’t get lost.

Let’s Step Back In Time

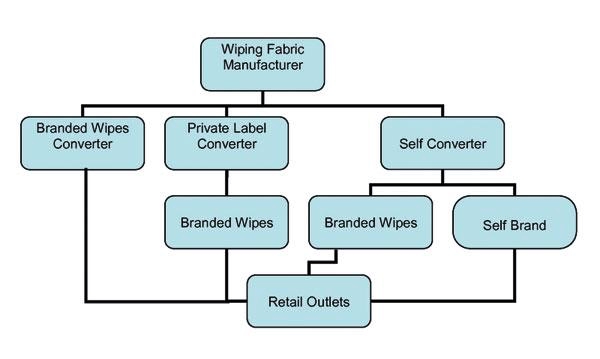

Yes, we know you don’t like to dwell in the past, and all you are interested in is How Baby Wipes are Made. But having a little bit of background is worth its weight in gold. So, this technology came into existence in the late 1970s, and then soon baby wipes were available for purchase. At the outset, only reputed companies came up with baby wipes as the equipment needed for their manufacture were expensive. But soon, they became affordable, and even smaller brands came up with their own baby wipes varieties. Today, these wipes are available in numerous different sizes and varieties.

All About The Design

Baby wipes have effective cleansing properties. Even heavy-duty clean-ups are possible with them. And you get all of that along with great ease of use. Since they are disposable, you don’t need to worry about cleaning them post-use. The fabric used for the wipes differ from one variety to another on the basis of absorbency, cost and durability. The cleansing solution is mild despite its fierce cleansing properties. Pre-moistened towels are kept in plastic tubs, generally. There are many amazing dispensing designs. Some of the dispensing designs have been patented.

Marketers have amazing new styles, formulations and sizes these days. And more get invented every day. You can choose from qualities like unscented, scented, pH-balanced, alcohol-free, greater absorbency, higher thickness, better stretchiness etc. Even products having natural ingredients are out on the market. So, definitely marketers are leaving no stone unturned to create better baby wipes in order to woo customers- existing or potential.

The Raw Materials Used

- For baby wipes, you need non-woven fabrics. Non-woven fabric is basically a mass of individual fibres pressed into sheets. Some of the most common fibres used are cotton, rayon, and then plastic resins such as polyester, polypropylene, polythene etc.

- Cleansing ingredients

- Water, acts as a dilution agent for the rests of the ingredients in the solution.

- Mild detergents called amphoteric surfactants for the prupose of cleansing.

- Humectants like glycerine or propylene prevent drying of the solution and moisturise the skin. Some varieties also contain oils and thickeners.

- Preservatives, fragrance, natural ingredients like oatmeal extract or aloe vera could also be present.

ALSO READ – How Wigs Are Made | History, Materials and Manufacturing

How Baby Wipes Are Made – The Manufacturing Process –

Non-Woven Preparation

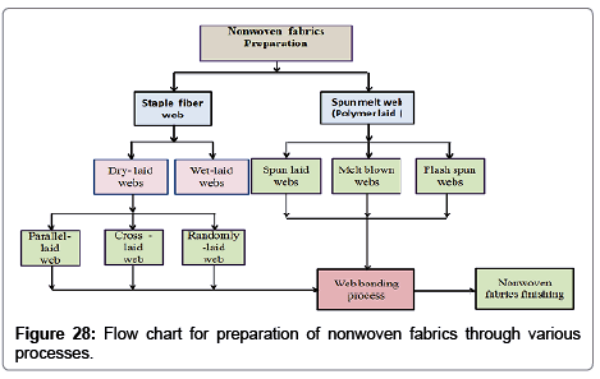

Non-woven fabrics are assembled by two basic processes- the dry laid process and the wet laid process.

- The dry laid method – There is a dry laid process called meltdown wherein non-woven fabrics are made from plastic resins. Molten plastic pellets are pushed through small holes. When these fibres cool down, they turn into sheets. Then metal rollers that are hot are run over the fibres to flatten them and bind them with one another.

- The wet laid method – Paste of fibres is made with water and chemicals. This slurry or paste is flattened out with rollers and then dried to create long fabric rolls. These rolls are then turned into thin sheets.

Formula Preparation

- The solution formula is generally made in batch tanks of a large size. The first ingredient that goes into the tank is usually water. The tank is heated a bit before the manufacture starts so that the ingredients blend well.

Non-Woven Treatment

- After the non-woven cloth is prepared, it is applied with the cleansing solution. This might involve multiple processes. Sometimes, the solution is sprayed on the sheets and at other times, the sheets are run through the solution.

- Now, the towelettes are packaged in foil pouches and sealed. An automated equipment creates the poches out of laminated foil and then a conveyor puts the non-woven cloths into the pouches. Now, moisturising liquid is packed into the towelette packets with the help of a liquid feed mechanism.

- Now, a heat sealer is used the seal the pouches.

The Packaging?

- The packaging involves multiple steps. The folding of the finished clothes, their stacking, and then their transfer to the main or final package are done in an automated manner.

Are Baby Wipes Quality Approved?

Knowing How Baby Wipes are Made is not enough; you need to know if they are the right quality for your baby. So, listen up! Starting from the plastic packaging to be used for the wipes and the non-woven fabric to the cleansing solution, each and every component of the wipes has to go through multiple quality testing phases. Even the final product is checked for microbial content, viscosity, pH etc. And just like that, we also have all the manufacturing and product details about the running shoes.

The Future Of Baby Wipes

Now, that you know How Baby Wipes are Made, you can clearly tell that the future looks pleasant for them. The varieties are constantly evolving. Makers are focusing more on economical product size to broaden their customer base. Travel friendly packs are also being introduced. And with the advent of better surfactants that are better cleansers and are much milder, the future only looks really bright for baby wipes.

Reply